Rapid Thermal Processing Performance just as OEM

Engineering-COMPONENTS & NEW PARTS

Sourcing solutions for Rapid Thermal Processing

For RTP as well, we are able to provide a selection of highly professional new parts. Especially for parts like the ball bearing for AMAT XE which has been cancelled by the OEM and therefore will be no longer available, it may be a real (and sometimes the only) alternative for our customers. It facilitates sourcing or makes it possible at all and prolongs the life cycle of the existing machinery.

We are offering following RTP new parts

AMAT Item Numbers

| Description | OEM Number |

| Upper Race RTP XE | 0020-39360 |

| Lower Race RTP XE | 0020-39361 |

| Upper & lower Race (complete) | 0010-19534 |

| Sleeve 33,6 mm | 0021-36086 (gold-coated) |

| Sleeve 16,8 mm | 0021-35055 (gold-coated) |

| Temp Probe Sapphire Pin RTP XE Sapphire Ligth Pipe for Pyro |

0010-15563/0190-35974 |

| 300 mm Radiance | 0010-18024 |

REFURBISHMENTS & REPAIRS

Used RTP components as good as new

Components used in Rapid Thermal Processing are exposed to extreme conditions and strain, so that they degrade very quickly. Additionally, their structures, regarding shape, build-up and/or composition of coatings are quite complex which makes competent refurbishment quite difficult. Equipment manufacturers mostly only offer expensive spare parts and no repair services at all. That’s where amcoss steps in – we offer a first-class repair service!

We refurbish following components:

And we calibrate

- Tempmatch tools for Centura, Radiance and Radiance+

- Sekidenko 2000

Regarding RTP a part of Circular Economy

„Circular Economy“ is being talked about everywhere. Even the EU-Waste Framework Directive has marked transition to circular economy one of its goals. Re-use instead of refuse is the slogan. As many products or materials etc. as possible should go into recycling instead of ending up at the end of the one-way road called waste dump – comprising all levels of parties involved in economic processes. As a matter of fact, this is also a big issue with Rapid Thermal Processing because the components used in this process are degrading very quickly and therefore have to be replaced or refurbished in a very exigent manner. So, with our refurbishment of RTP components we not only support you in increasing cost efficiency, but especially in contributing to recycling, conserving resources and to improving your impact on the environment as a whole.

COMPLETE REFURBISHMENT OF RTP LAMP HOUSES

Complex, reliable, economic

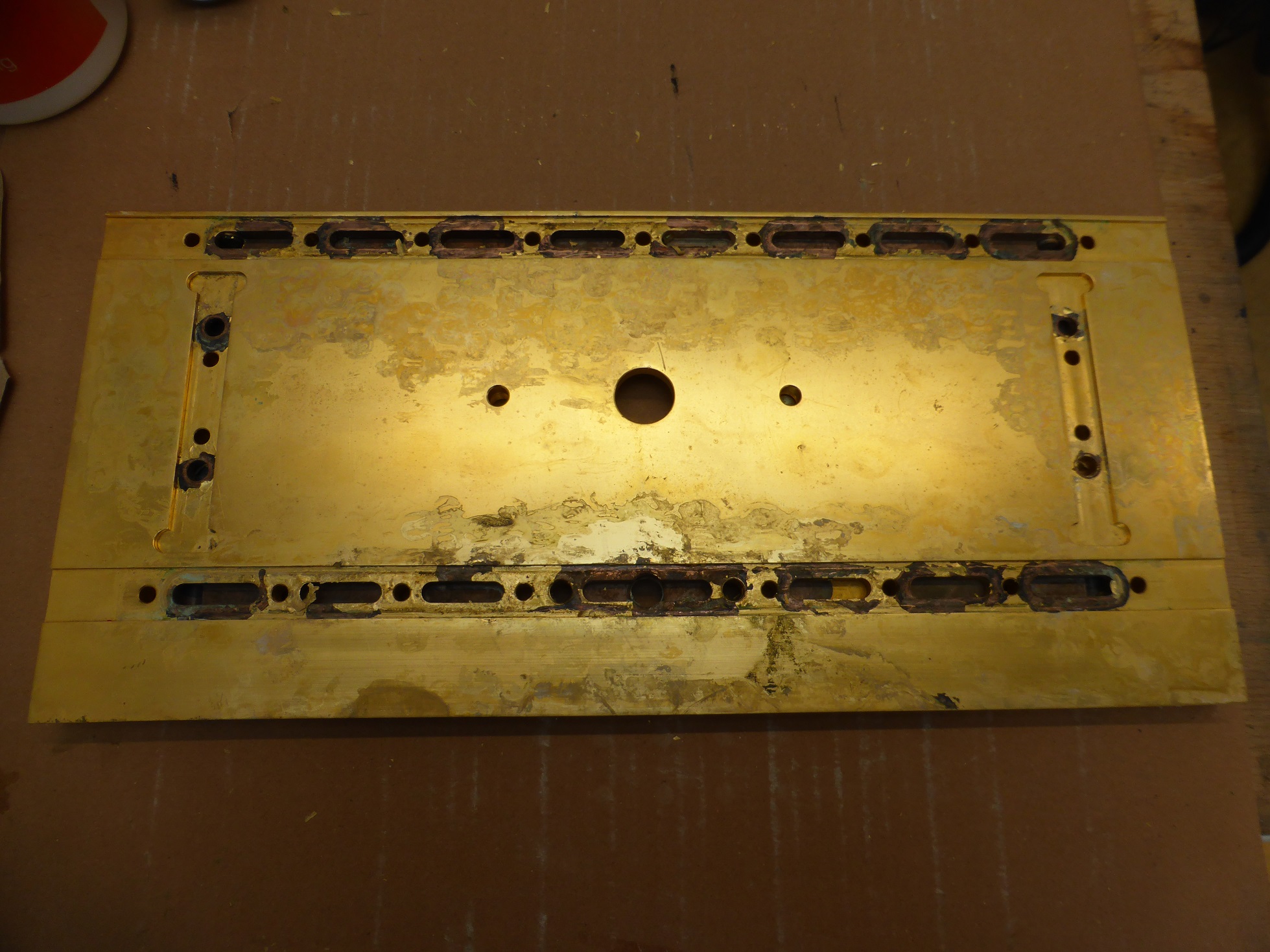

Untight welding seams, mechanical defects, fissures, chemical deposits and surface damages can lead to reduced functionality of a lamp house. Even though lamp house refurbishment, due to its complex structure is a very challenging process, amcoss has developed a professional refurbishment procedure. Therefore, our experts are carrying out various process steps as e.g., chemical cleaning, leak tests, mechanical treatments and welding of defective parts. The result is a refurbished, fully functional lamp house, being a lot more economic than a new one.

Lamp houses AMAT item numbers

0040-35966 (gold-coated)

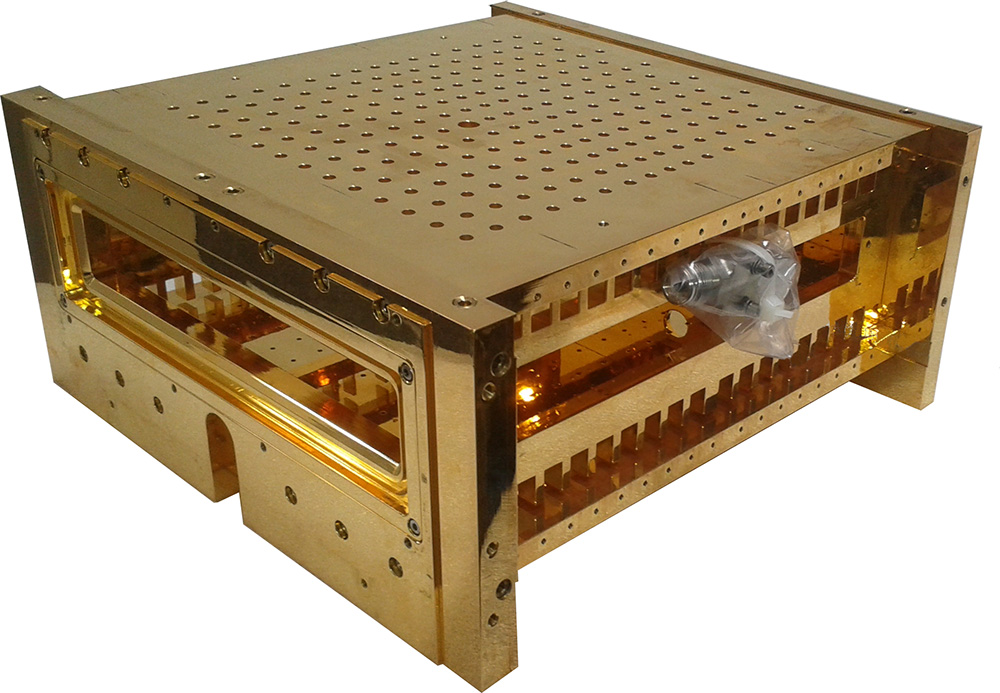

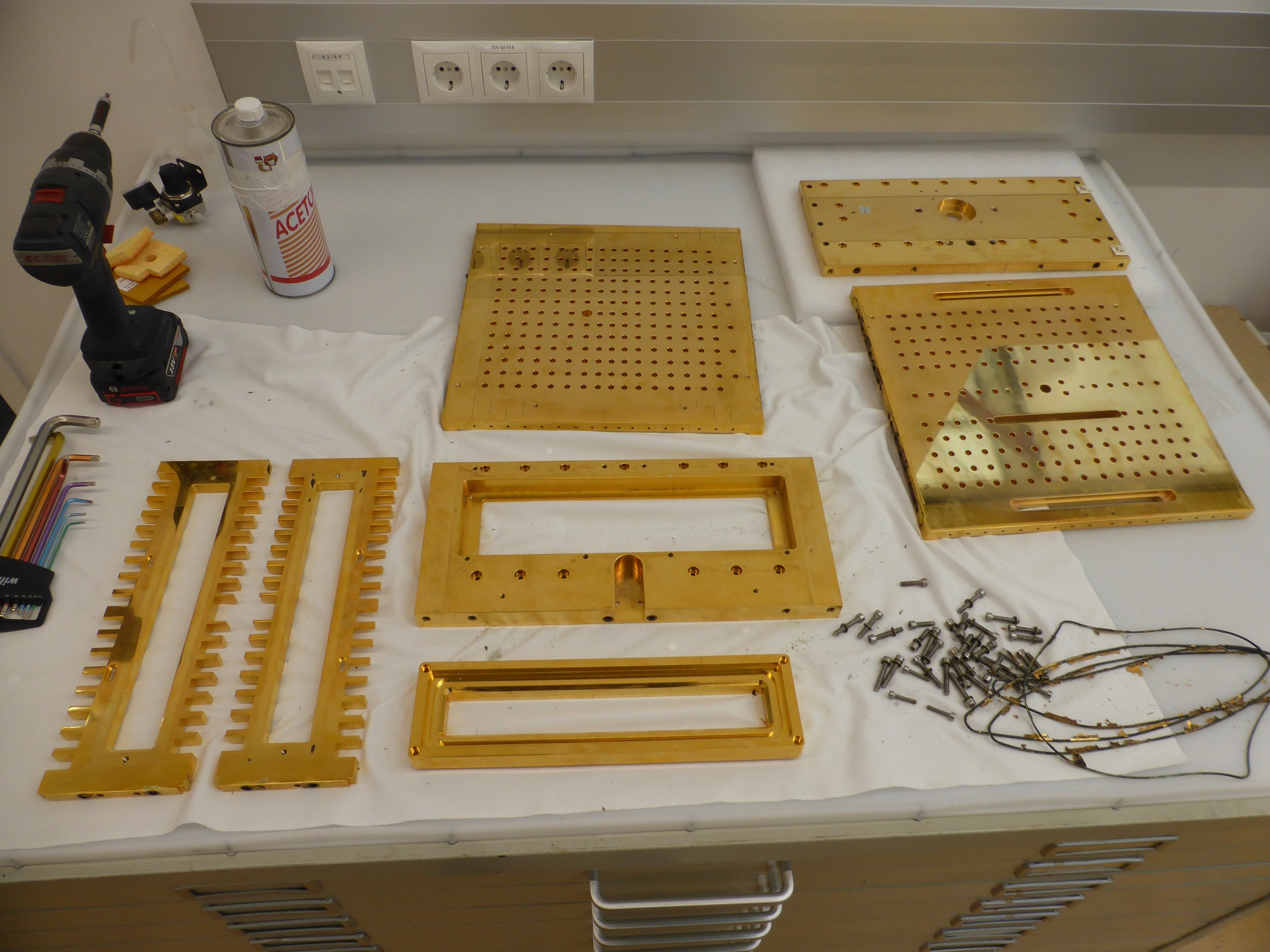

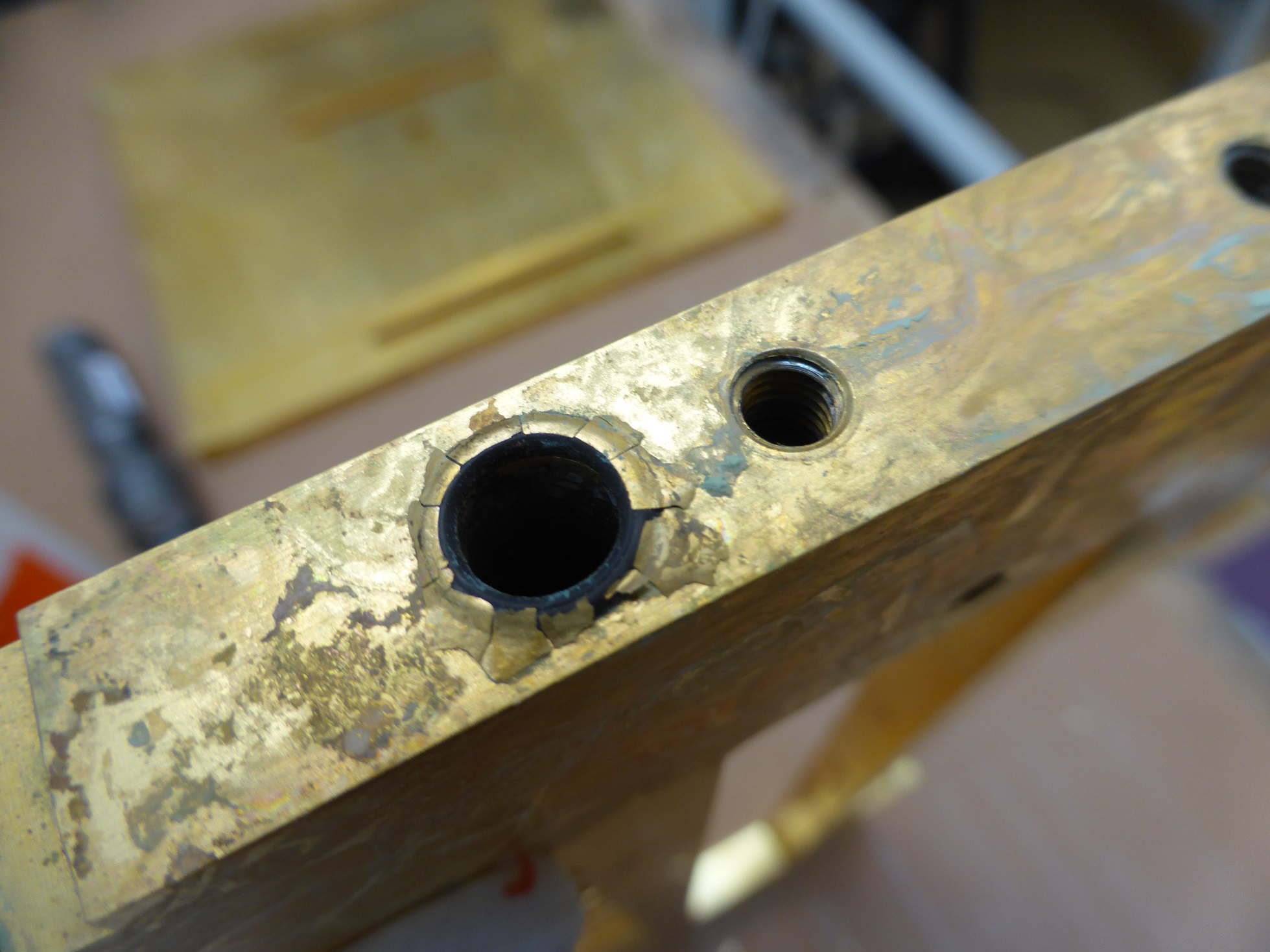

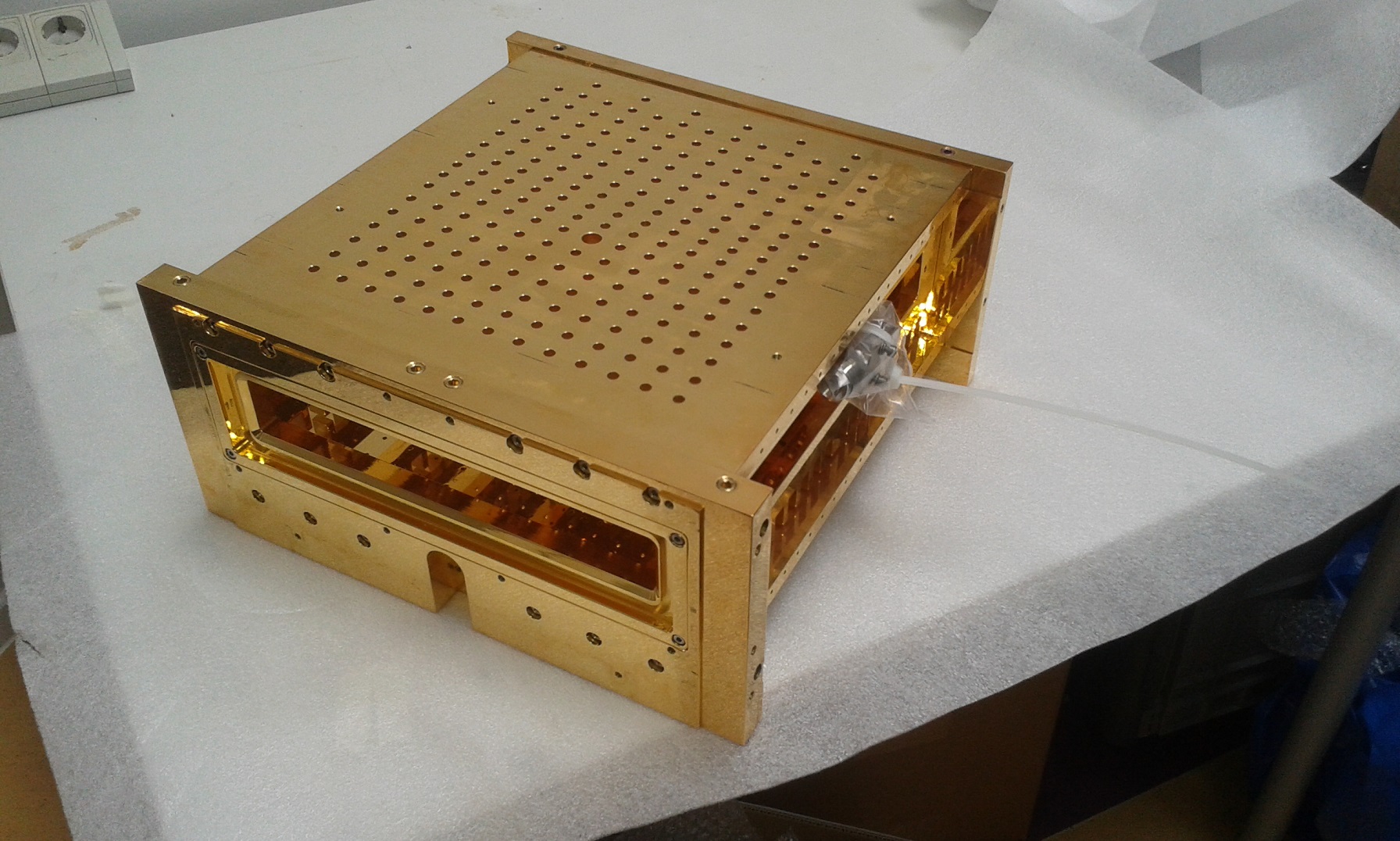

RepaIr OF mattson reaCTORS SHS 2900

It’s all about coating quality and tightness

A Mattson reactor is a very complex construction. Due to extensive exposure the gold

coating degrades and leaks appear. In a time-consuming process the reactor is being completely dismantled to find out about the extent of damage. Afterwards we de-coat, mechanically rework, clean and finally re-coat the parts. After assembly and leakage test the Mattson does not only look like a new one it also works that way.

Final Leakage test and quality control

After successful refurbishment and assembly Mattson reactors SHS 2900, as well as lamp houses will additionally be subject to a special high-temperature, water-pressure leakage test. In this test real working conditions are being simulated: For 24 hours water heated up to 90°C will be pumped through the tubes and cooling pipes with a pressure of 5 bar. Water temperature will vary between 20°C and 90°C. So, possible leaks can be detected and consequently be repaired. This guarantees highest quality and best possible functionality.

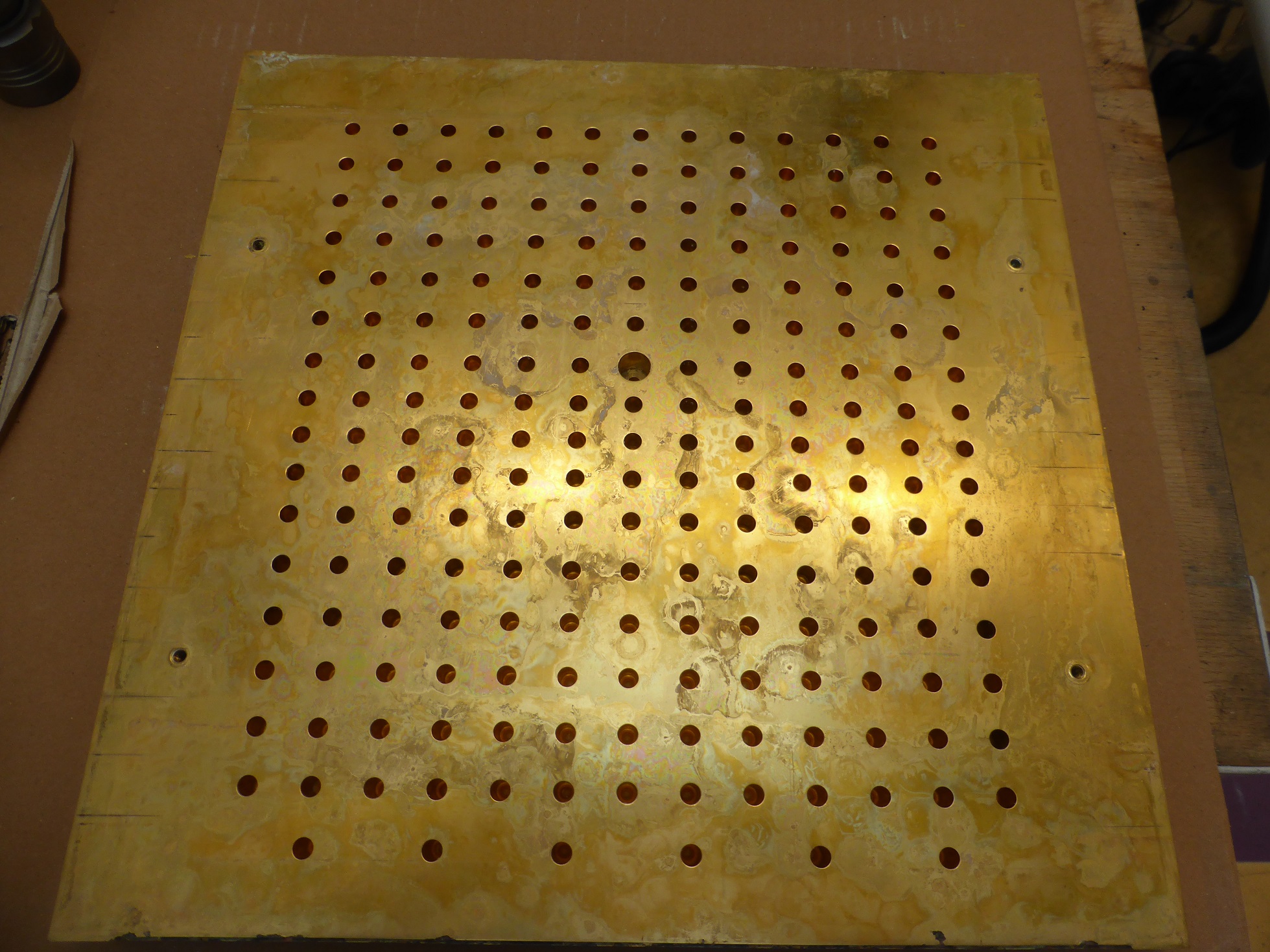

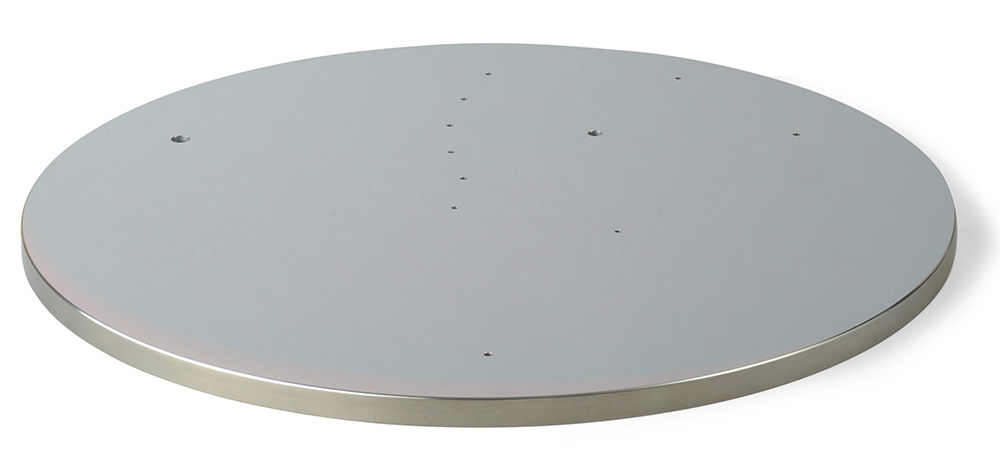

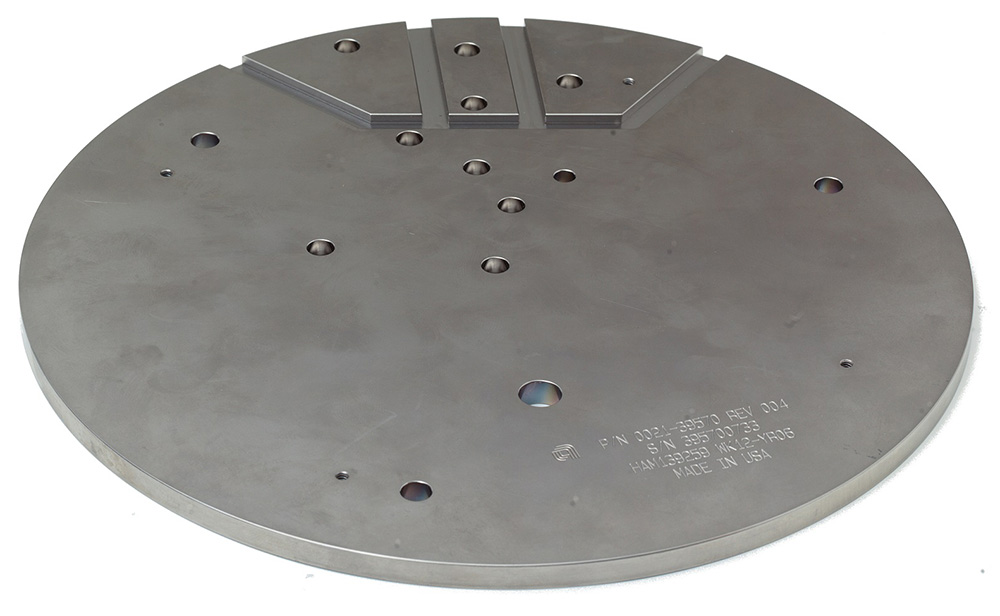

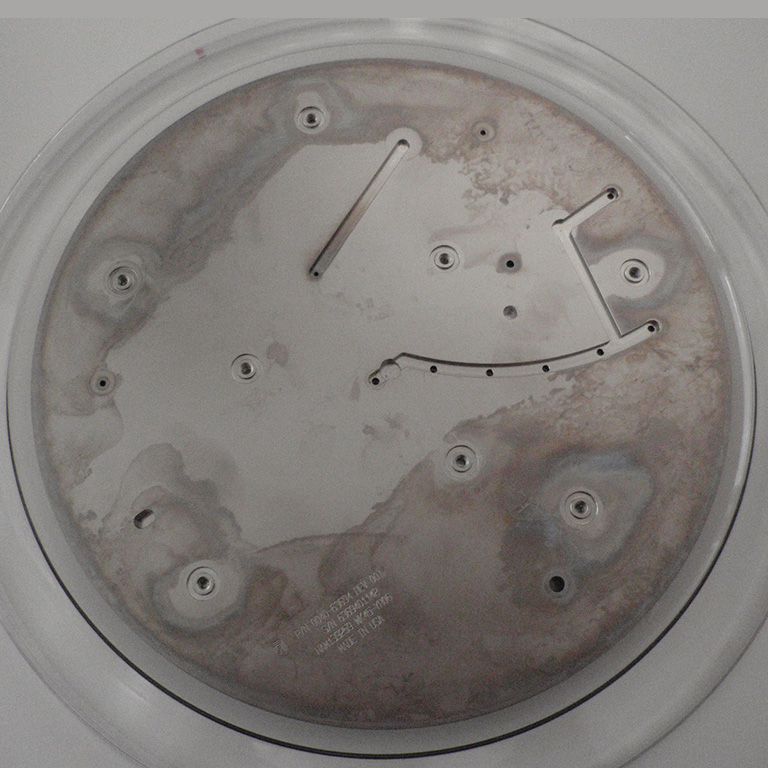

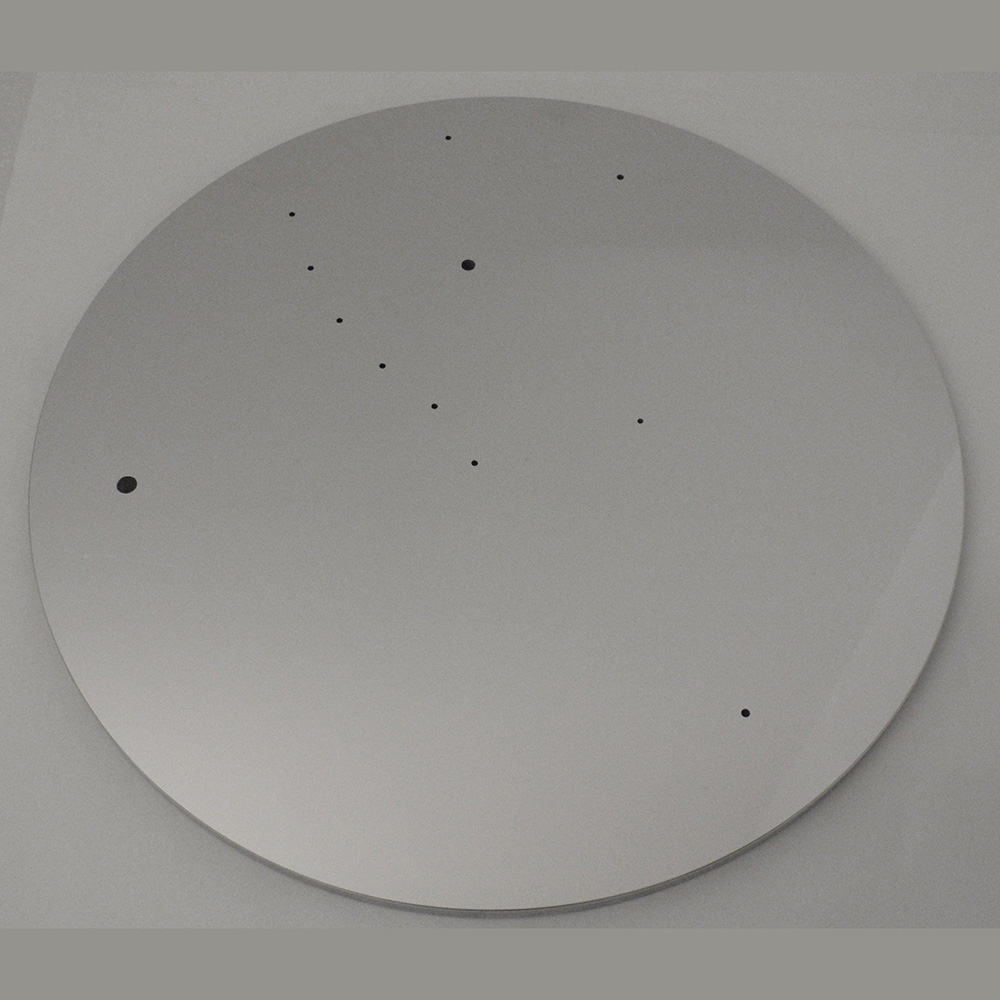

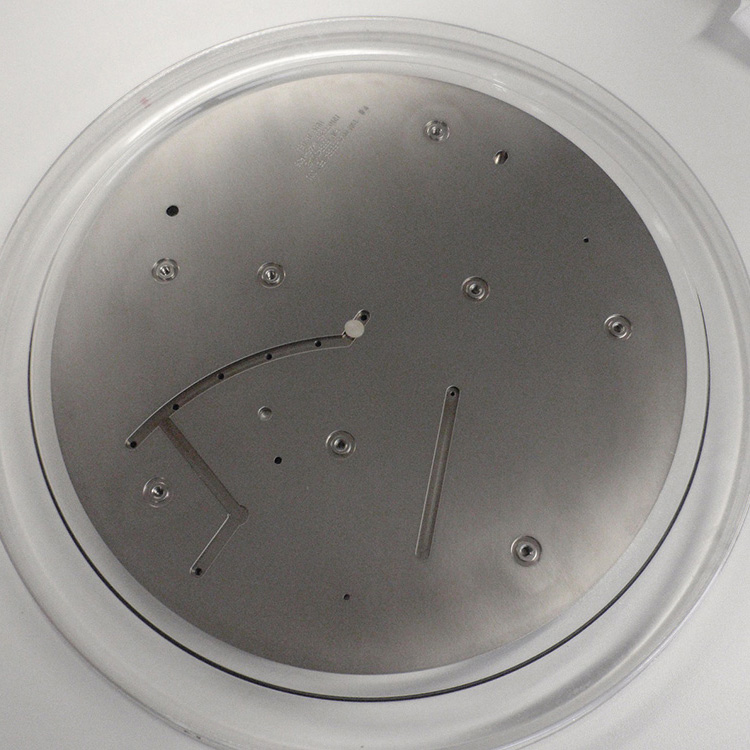

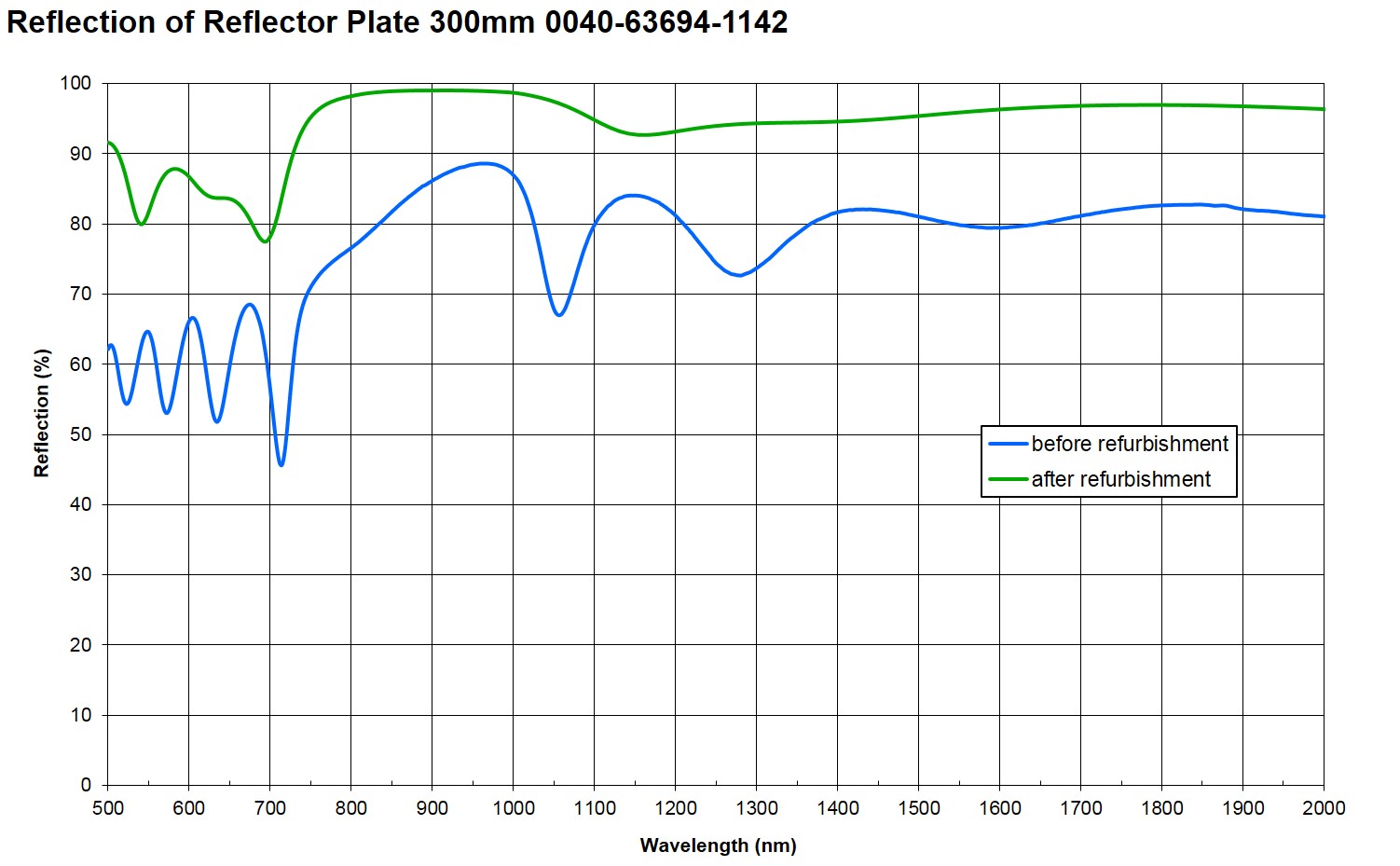

Refurbishment OF AMAT RefleCTOR PLATES

Reflection and process security without compromises

During refurbishment your used reflector plates are being de-coated, polished and afterwards re-coated.

This repair process restores the maximum reflection capacity in all important and relevant wavelength ranges. We have developed an optimized, special multi-layer coating, making absolutely sure to only use materials specified by the OEM, so that no „foreign“ substances might get into the process chamber. The coating design and the technology applied guarantee extremely homogeneous, consistent and long-living coatings, the durability of which prevent early chipping and/or corrosion.

Reflector plates AMAT item numbers

| Description | For machine | OEM number |

| Reflector Plate Refurbish | AMAT RTP XE | 0021-35008 |

| Reflector Plate 300 mm Refurbishment | AMAT RTP XE | 0040-63694/ 0040-44027 |

| Refurbishment Reflector Plate BPSG 200mm XE | AMAT RTP XE | 0021-39570 |

| Refurbishment Reflector Plate Radiance 200 mm | AMAT Radiance | 0020-08621 |

| Refurbishment Plate, Reflector, 200mm XE, Corrosion RE | AMAT RTP XE | 0021-03721 |

| Reflector Plate 300 mm Radiance Refurbishment | AMAT Radiance | 0040-70629 |

| Reflector Plate 300 mm Refurbishment | AMAT Radiance | 0041-06278 |

| Reflector Plate 300 mm Refurbishment | AMAT RTP XE | 0041-12192 |

| Refurbishment of Reflector Plate Chamber Bottom | AMAT Mod 1 | 0021-35163 |

| Reflector Plate 300 mm Refurbishment | AMAT Radiance | 0041-12156 |

| Refurbishment of Reflector Plate 300mm | AMAT Radiance | 0041-12179 |

| Reflector Plate 300 mm Refurbishment | AMAT Radiance | 0041-27029 |

| Reflector Plate 200mm Refurbish | AMAT XE | 0021-35009 |

| Reflector Plate 12″ 0351G BesSun | AP |

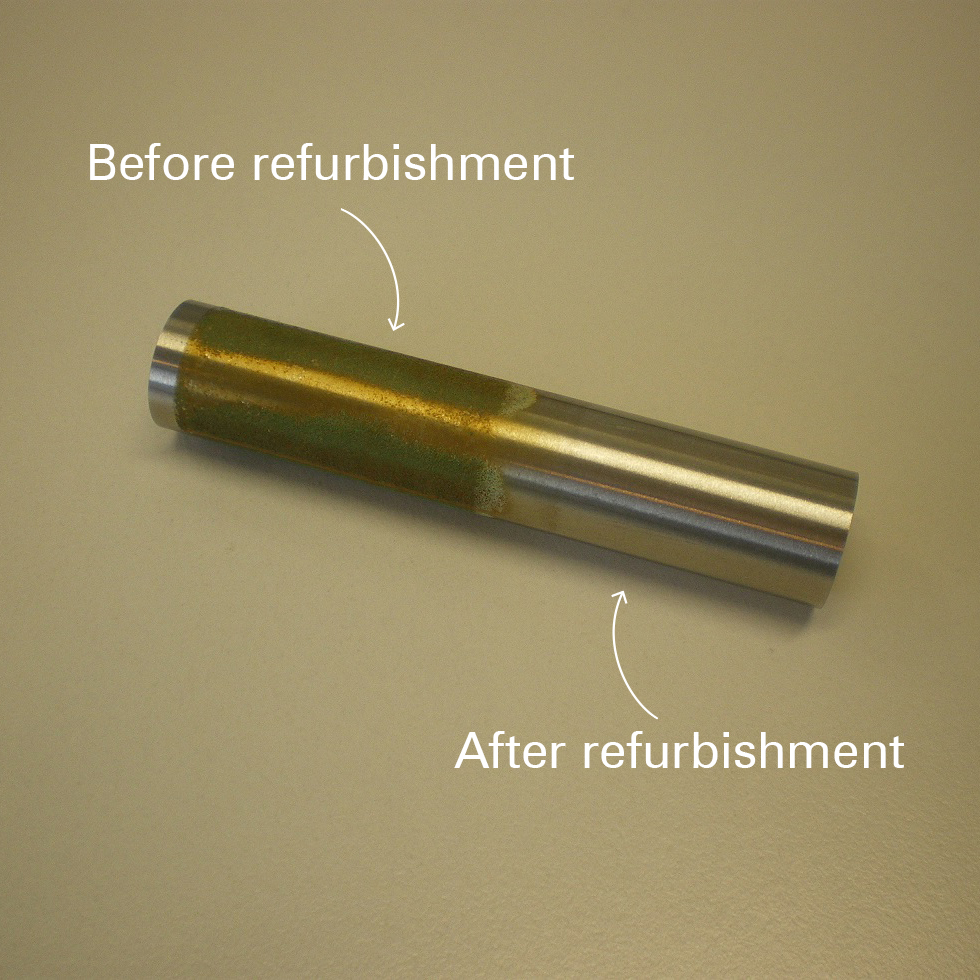

Refurbishment OF RTP BALL BEARINGS FOR AMAT RTP XE

A well-rounded solution

The surface of a ball bearing is often being scratched and so the ceramic balls damage the PVD coating and the surface beneath. This leads to the fact that concentricity as well as axial lateral run of the bearing get off tolerance. Other consequences are high noise levels and particle buildup. amcoss offers new ball bearings (second source) as well as exclusive refurbishments (de-coating, mechanical treatment, polishing, new PVD coating – the same as OEM coating) – and both at attractive, unrivalled prices. Parameters and quality of our ball bearings correspond to those of an OEM component, but they are a lot more sustainable.

Ball bearings AMAT item numbers

| Description | OEM number |

| Upper Race RTP XE | 0020-39360 |

| Lower Race RTP XE | 0020-39361 |

| Upper & lower Race (complete) | 0010-19534 |

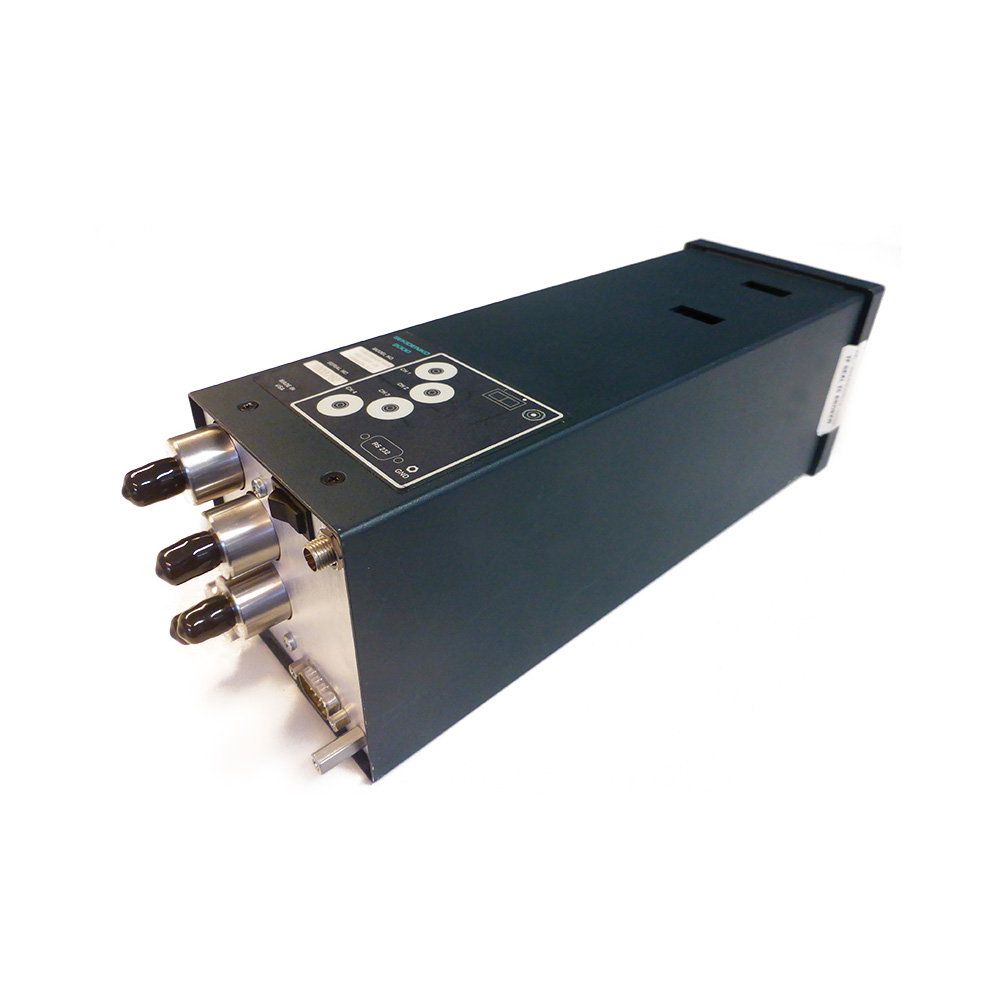

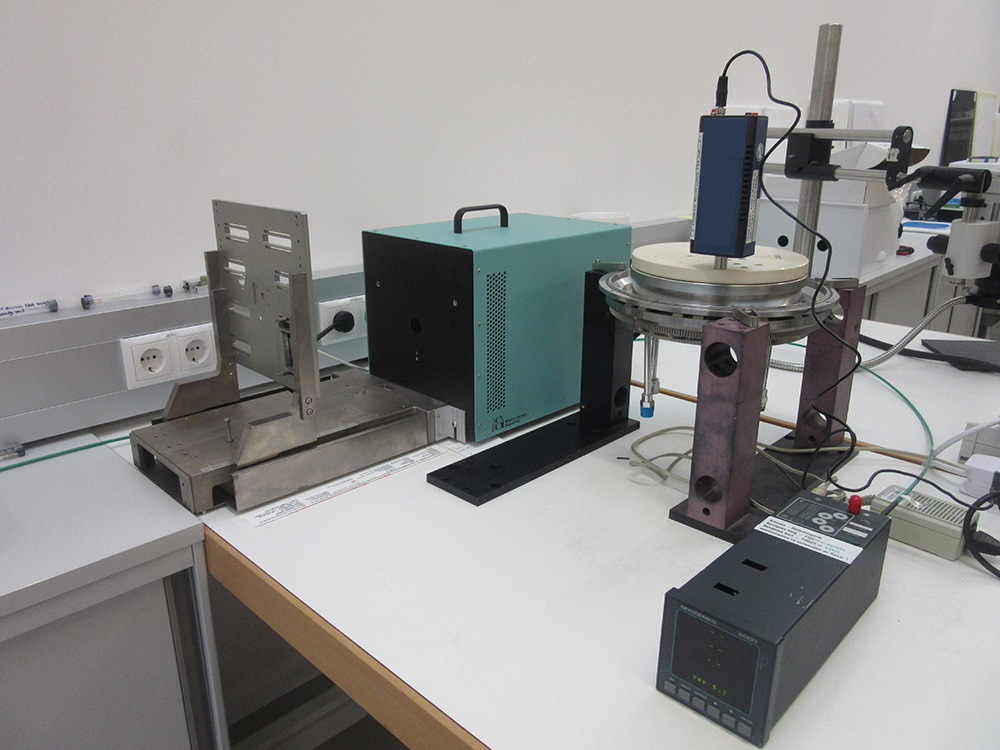

CALIBRATION OF

Tempmatch Tool, Sekidenko 2000 & Radiance (+) Tester

Inspection with highest precision

We calibrate following inspection tools for AMAT Centura XE, Radiance und Radiance (+)

At first, we will examine whether any optical or electrical components have degraded and exchange them if necessary. Afterwards we will carry out exact measurements and calibrations on various testing devices and with the help of our Black Body Furnace. This procedure ensures best quality of our services for you. At the end of the refurbishment process we generate an individual test report for each refurbished and calibrated tool which together with the device is being provided to the customer. Our service will be a lot more economic than an OEM refurbishment.

AMAT inspection tools item numbers

| Description | OEM number |

| For Centura XE | 0242-34144, 0242-24658 |

| For Centura Radiance (+) | 0242-45555, 0242-34148 |

Sekidenko 2000

| Description | OEM number |

| K1-3 für Centura XE | 0190-36523 |

| K1-4 für Centura XE | 0190-36524 |

Download Flyer RTP Overview

Download Flyer Gold Refurbishment

RTP AMAT item numbers