amh Process temperature control with heat exchangers & chillers

amh Heat Exchangers & Chillers

Individual solutions for process heating and cooling

amcoss temperature control units replace conventional, expensive, or even no longer available Heat Exchangers and Chillers as e.g. AMAT 0 & 1, Neslab Steelhead and Endura, LAM TCU, Beta Tech, as well as HX150/HX300 and other. We prepare and fit them according to our customers´ demands. Thanks to compatible, proprietary interfaces, which we at amcoss configure and install (replacing standard interfaces) our devices are immediately ready for „Plug-and-Play“ operation at our customer´s equipment. This means our customers will receive personalized devices adjusted to their own process requirements and do not have to find and realize solutions on their own. This again simplifies their sourcing processes and increases cost-effectiveness.

Price-performance ratio of amcoss devices is excellent, and they are even more economic than OEM chillers. So, time and money can be saved.

Robust design, long lifetime

amcoss amh temperature control units are robust, reliable and efficient – aspects that are indispensable for sustainable operation. The use of quality parts and components, an uncomplicated, robust construction and supportive features as, e.g. the resistivity sensor, do prolong lifetime of our devices, reduce maintenance demand and do guarantee reliable operation. Because they are fit to replace temperature control units specially designed for certain processing equipment which, however, is no longer offered or serviced by the OEM, our amh devices can even increase the period of use for those equipments. Together with low energy consumption and the advantages of the „Plug-and-Play“ option for simple operation, all of that guarantees best possible efficiency with regard to processes, costs and operability.

amh heat exchangers 30 – 95 °C

amh chillers 5 – 60 °C

amh heat exchangers

For temperatures 30 – 95 °C

Our amh heat exchanger series covers a wide temperature range from 30 °C to 95 °C. The devices replace old or expensive AMAT, Neslab and other OEM temperature control units and work perfectly with a variety of machines and processes. amcoss amh devices are a powerful and cost-efficient alternative for the microchip and semiconductor production.

amh 080 — replacing AMAT 0 und 1 heat exchanger & Neslab Steelhead

- Temperature range of process water: 30 – 95 °C

- Heating / cooling power: 6 kW / 6 kW

- Pump capacity: Max. 5,5 bar; typical operation: 5 bar @ 24 l/min

- Number of process water channels: Max. 3 + 1 for resistivity regulated, externe DI-water cartridge

- Connector types for process water: On request – e.g. Parker, Swagelok etc.

- Operating voltage: 3 x 380 Vac oder 3 x 200-208 Vac

- Dimensions W / D / H: 310 / 670 / 750 mm

- Weight: 60 kg

- Remote interface: AMAT 5000 analog, digital IO or CHX (RS485)

- DI-water cartridge: Extern – resistivity regulated lifetime extension

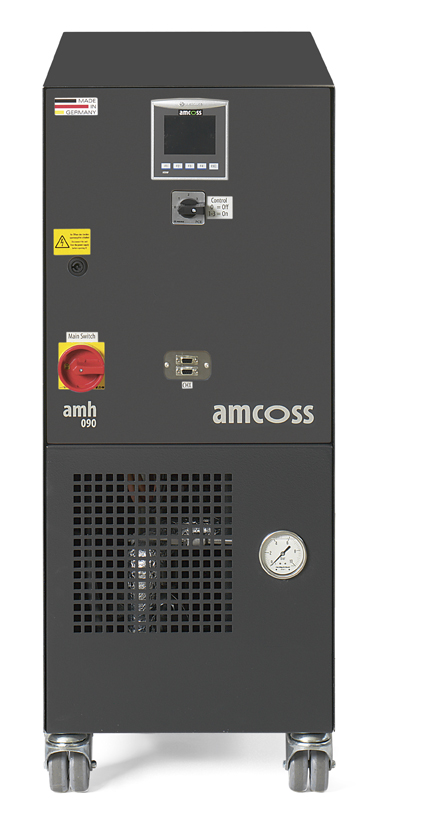

amh 090 — replacing Neslab Steelhead, Neslab Endura, TEL MB Square

- Temperature range of process water: 30 – 95 °C

- Heating / cooling power: 6 kW / 8 kW

- Pump capacity: Max. 8 bar; typical operation: 5 bar @ 40 l/min

- Number of process water channels: Max. 4 + 1 for resistivity regulated, external DI-water cartridge

- Connector types for process water: On request – e.g. Parker, Swagelok etc.

- Operating voltage: 3 x 380 Vac oder 3 x 200-208 Vac

- Dimensions W / D / H: 410 / 820/ 1020 mm

- Weight: 100 kg

- Remote interface: AMAT 5000 analog, digital IO or CHX (RS485)

- DI-water cartridge: External – resistivity regulated lifetime extension

amh 090-S — compatible with Mattson Helios III and other

- Temperature range of process water: 30 – 95 °C

- Heating / cooling power: 6,5 kW / 40 kW

- Pump capacity: Max. 8 bar; typical operation: 5 bar @ 210 l/min

- Number of process water channels: Customized

- Connector types for process water: G2″ or G1,5″ ID thread

- Operating voltage: 3 x 400 Vac

- Dimensions W / D / H: 530/ 1500/ 1220 mm

- Weight: 215 kg

- Remote interface: Customized

- DI-water cartridge: Internal – resistivity regulated lifetime extension

Highlights

Plug & Play function

Plug & Play function

With the amcoss Heat Exchanger our customers receive a ready-to-use solution: There is no need for own adaptations or adjustments to operate their equipment. Our device has been adequately prepared and can be connected and operated immediately. This saves time and consequently, costs.

Robust & powerful

Robust & powerful

Especially the inner life of our equipment is characterized by its robust construction. The whole piping system is made from stainless steel, as is the powerful high-quality pump. This guarantees long lifetime and minimum service demand. The size of the heating unit has been well balanced and adapted to the dimensions of the heating rod surface. Therefore, there is less strain on the heater and the fluid, which leads to an increase in heating capacity of the element as well as its lifetime.

Different operational modes & displays

Different operational modes & displays

- Possible operation modes: local, CHX interface, DIO

- Various displays: system pressure, temperature (0,1°C accuracy), resistivity of process water, etc.

- Three-step microprocessor controller with temperature control and automatic optimization

Resistivity sensor & control

Resistivity sensor & control

amcoss amh heat exchangers are equipped with a resistivity sensor. This sensor controls the resistivity of the cooling medium and, also regulates its deionization. As soon as resistivity falls below a threshold value set by the customer the medium is being run over a deionization cartridge. As soon as the threshold value has been reached again, deionization automatically stops.

Advantages: resistivity of the cooling medium remains stable and so does the whole process. The deionization cartridge lasts longer for it is not being constantly used. Consequently, operational costs will be reduced

Various interfaces & connectors

Various interfaces & connectors

Our amcoss heat exchangers support various remote interfaces such as Digital IO, CHX (RS-485) etc. and may be fitted with various, selectable connector types. Besides, our customers may individually choose from various couplings (Parker, Swagelok, etc.) for liquid media. The number of connectors for in- and outlets is being determined by the customer. So, the device becomes very customer-specific which means that there is more flexibility and a greater variety of possible applications.

Cost-cutting product features

Cost-cutting product features

Low operating costs

Our powerful pump is very economic and energy-saving. All tanks and pipings are heat insulated, which minimizes heat loss through radiation. Lifetime of the deionization cartridge is prolonged, because it is only being opened by the resistivity sensor controlling the cooling medium, if necessary.

Low maintenance costs

amcoss temperature control units only use high-quality components. We guarantee a 2-year warranty. Structured layout of the components within the device and good accessibility make it easy for the customers’ service personnel to carry out maintenance. All that helps to bring down repair and maintenance costs.

Low procurement costs

Compared to other manufacturers’ devices our equipment stands out due to its excellent price-performance ratio.

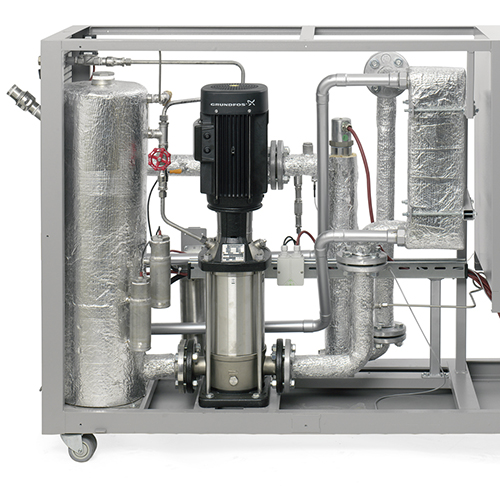

amh chillers

For temperatures 5 – 60 °C

amcoss amh chillers do, in various temperature ranges, cover temperatures from 5 °C – 60 °C. We offer special, adapted and already qualified chillers. They do, for example, replace LAM, LAM Dual Loop as well as AMAT Centura chillers and are mainly used for cooling and climatizing chambers and ozone generators, but also for electrostatic chucks and electrodes.

amh 030 / 030-AC — replacing Betta Tech CU700

Water- or air-cooled (ac), proven and adapted SMC chillers.

- Temperature range of process water: 5 – 60 °C

- Heating / cooling power: 3,0 kW @ 20 °C

- Pump capacity: Max. 7 bar; typical operation: 3 bar @ 13 l/min

- Cooling: Water or air (ac)

- Operating voltage: 1 x 200 – 230 Vac

- Dimensions W / D / H: 377 / 500 / 615 mm

- Port size – cooling water: G 1/2

- Weight: 43 kg

- Remote interface: LAM/SPTS

- Local mode: Yes

amh 030-2 — replacing LAM TCU2080 (dual loop)

2 amh 030 on a special rack.

- Temperature range of process water: 5 – 60 °C

- Heating / cooling power: 3,0 kW @ 20 °C

- Pump capacity: Max. 7 bar; typical operation: 3 bar @ 13 l/min

- Cooling: Water or air (ac)

- Operating voltage: 1 x 200 – 230 Vac

- Dimensions W / D / H: 511 / 953 / 1700 mm

- Port size – cooling water: G 1/2

- Weight: 190 kg

- Remote interface: LAM/SPTS

- Local mode: Yes

amh 050 — replacing Neslab HX150 (CHX) and Neslab HX300

Water-cooled, proven and adapted SMC chillers.

- Temperature range of process water: 5 – 60 °C

- Heating / cooling power: 4,7 kW / 6 kW

- Pump capacity: Max. 5 bar; typical operation: 3 bar @ 20 l/min

- Cooling: Water

- Operating voltage: 1 x 200 – 230 Vac

- Dimensions W / D / H: 377 / 592 / 976 mm

- Port size – cooling water: G 1/2

- Weight: 67 kg

- Remote interface: AMAT Standard P5000/Centura/CHX

- Local mode: Yes

An optional tray for placing of external DI water cartridge mounted on the backside of the chiller is available.

Highlights

Plug & Play function

Plug & Play function

With the amcoss Chiller our customers receive a ready-to-use solution: There is no need for own adaptations or adjustments to operate their equipment. Our device has been adequately prepared and can be connected and operated immediately. This saves time and costs.

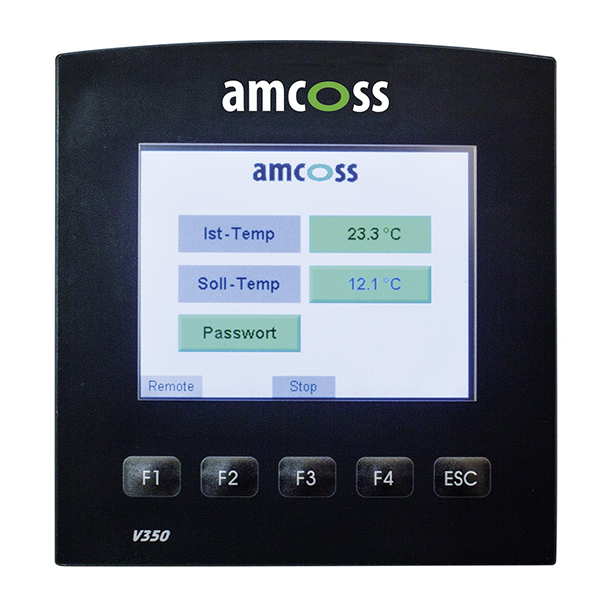

Proprietary controller

Proprietary controller

The standard interface is being replaced by a proprietary controller which is connected to a control touch screen on the top cover of the chiller

- for selection of local or remote mode

- for adjustment of actual & target temperature

- with password entry

- for selection of different parameters

- with display for warnings and alarms

An extra connector is being fixed to the housing. So, operation at customers´ equipment as well as comfortable operation through operator is being facilitated.

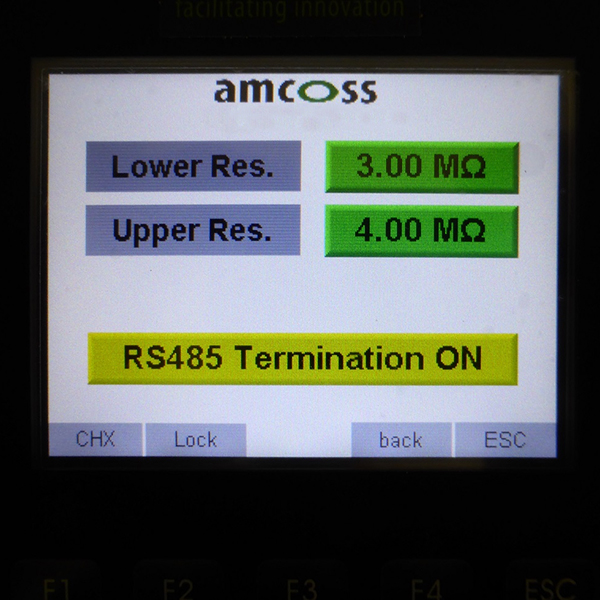

Various interfaces and connectors

Various interfaces and connectors

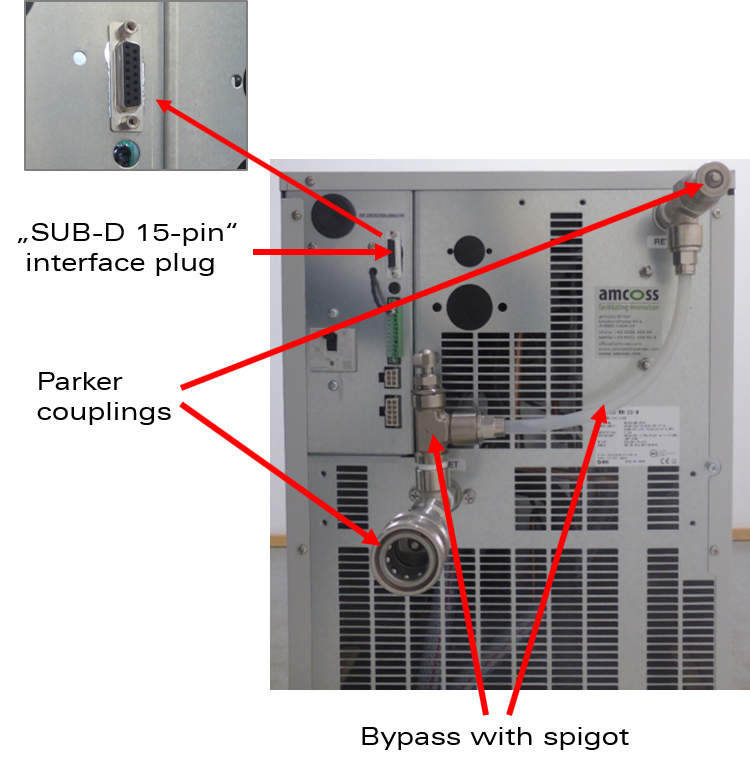

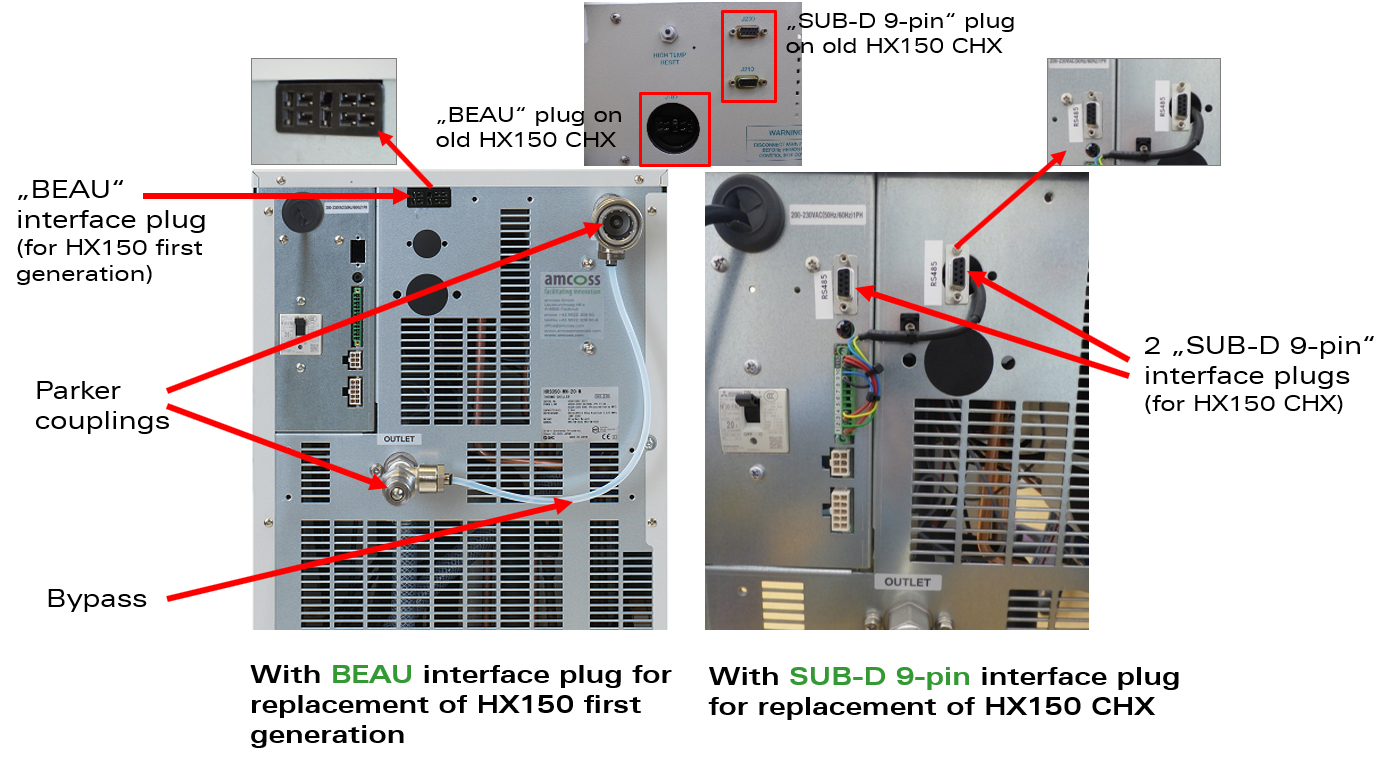

Our amcoss chillers support various remote interfaces such as AMAT 5000 analog, CHX (RS485) as well as LAM TCU and may be equipped with various selectable connectors (SUB-D 15 Pin, SUB-D 9 Pin, BEAU etc.). In addition, our customers may choose from various fluid couplings for liquid media as, e.g. Parker stainless steel express couplings with bypass or magnetic valve, Swagelok, etc. So, the device becomes very customer-specific which means that there is more flexibility and a greater variety of possible applications.

Individual special components

Individual special components

Certain options for configuration with special components can be individually chosen by every customer. So, there are the possibilities of conductivity control or resistivity measurement. The resistivity sensor controls the resistivity of the cooling medium and, also regulates its deionization. As soon as resistivity falls below a threshold value set by the customer the medium is being run over a deionization cartridge. Has the threshold value been reached again, deionization will automatically stop. Resistivity is monitored by the controller and shown on the display.

Advantages: resistivity of the cooling medium remains stable and secure and so does the whole process. The deionization cartridge lasts longer for it is not being constantly used. Consequently, operational costs will be reduced.

Various temperature ranges

Various temperature ranges

We offer chillers for different temperature ranges. Therefore, the best suitable device for your desired operating temperatures may be individually chosen. So, you won´t be off target with either too much or not enough cooling capacity. That way customer processes can be optimally supported.

Special dual loop replacement

Special dual loop replacement

With our amh 024-R or 030-R we have created a solution that enables our chillers to even replace LAM dual loop temperature control unit TCU2080. The specially developed rack can hold two amh chillers on two levels and has been equipped with a proprietary controller. Both chillers are being plugged into the necessary connectors integrated within the rack and so connected to the processing equipment to be controlled.

Configuration examples

1) amh-060 with stainless Parker express couplings with bypass and SUB-D 15-pin interface plug for replacement of HX300

2) amh-050 with BEAU & SUB-D 9-Pin interface plugs

Download Flyer Heat Exchanger & Chiller

Download Flyer amh 032

Download technical data